It all begins with the selection and germination of the most fitting spirit grains, which when stored in the ideal conditions birth the sugar base for our spirits.

Mashing allows for better availability of starch, where the grain is milled and agitated together with great precision and skill at favourable temperatures.

Fermentation is overseen by experts under controlled environments to convert the grain mash base to form alcoholic compounds through yeast culture.

Once fermentation is achieved to the right measure, the wort is double distilled to deliver optimum alcohol by volume ratios.

Depending on the blend, a variety of casks or bespoke barrels are used to infuse sensorial properties of taste, aroma and colour to the final spirit, by allowing it to mature over a period of time.

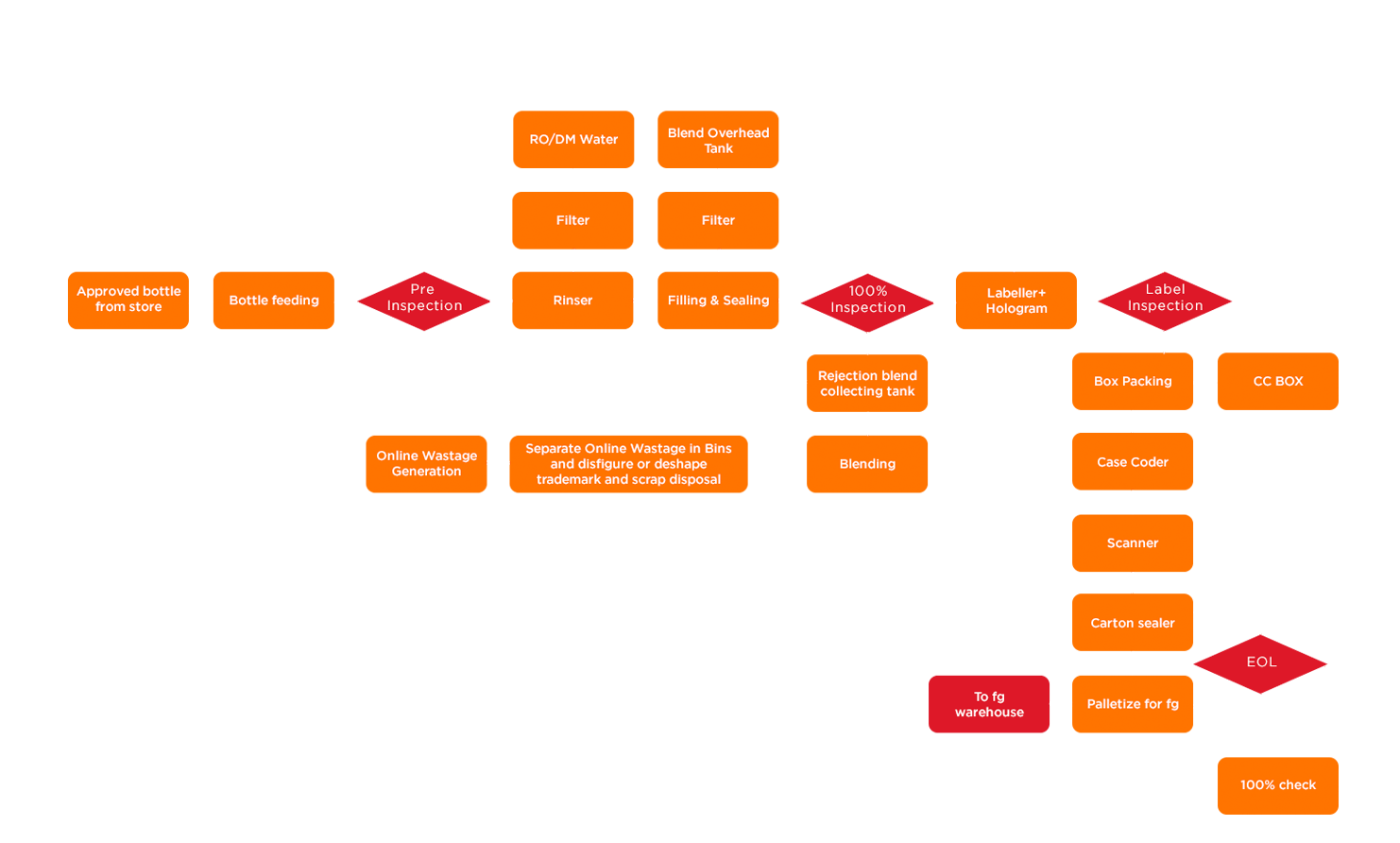

The final stage of bottling admirable experiences occurs under close scrutiny to ensure prevention of contamination of the final product. At ABD, we also constantly innovate for more effective, tamper-proof capping technologies, which bolster the integrity of our packaging.